Steel detailing is a specialist area of structural drafting. A steel detailer interprets architectural and structural engineering drawings to gain a thorough working knowledge of the overall design intent of a building.

What We Do

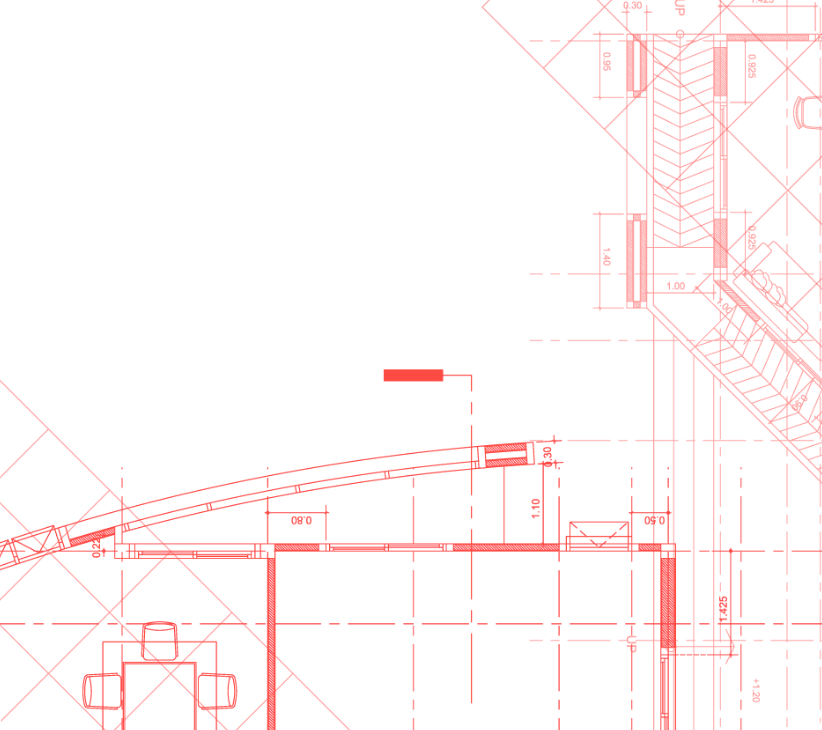

Also called Detail Drawings. They specify the exact detailing requirements for every individual steel element involved in the construction process that needs to be made by the fabricator (in-shop). Shop Drawings include details about material specification, component sizes and exact dimensions, welding, bolting, threading and all of the remaining details required by the fabricator to produce structural elements that align to product specifications & drawings. Such drawings pertain to fabrication shops only and thus contain little or no information about the erection and installation of steel members they depict

Erection drawings are used to show illustrations for onsite steel erectors to properly & precisely erect steel structures. These drawings portray dimensioned plans and specify the position of each steel component inside the overall steel structure. They provide precise and exact information regarding the placing of each component, the installation requirements, and any associated field operations such as installation, bolting, welding and wedge anchor installation.

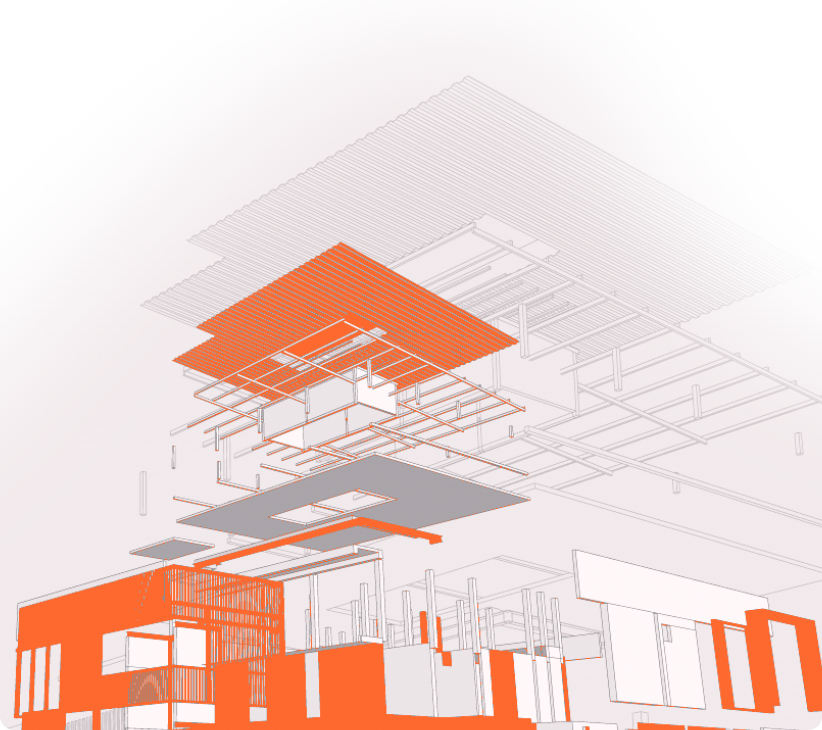

Today, manual drafting has been largely replaced by computer-aided drafting (CAD). Almost all steel detailers now create drawings on a computer, using software specifically designed for steel detailing. The two most common computer applications in use today are Tekla Structures and SDS/2. With these softwares, the detailer literally builds the project in a 3D model before producing detailed shop drawings.

Steel Detailers must comply with the requirements of the design drawings and with all industry standards and protocols, such as those established by the American Institute of Steel Construction (AISC). The detailer is usually not responsible for design, including structural strength, stiffness, and stability (which are the responsibility of the structural engineer), or major dimensions of the structure and compliance with relevant building codes (which are the responsibility of the architect).

Part of the structural analysis process includes the use of structural elements which are used to split a complex structure into simpler elements.

BENEFITS OF USING BIM-BASED STEEL DETILING SOFTWARE

BIM software allows automatic generation of high-quality shop drawings, general arrangement drawings and assembly drawings. Also, design changes can be easily accommodated.

Model-based detailing process engages in BIM workflow easily. So one can use 3D models to collaborate with the architects and designers more effectively. There is no manual recreation of data and therefore the risks of errors reduce.

The model-based approach of steel detailing allows for the reduction of redundant data by removing errors. It also reduces the waste created in fabrication shops and fields as the information is derived from a consistent information-rich steel model.

The ability to quickly & automatically generate steel detailing drawings result in cost and time optimization.

You will get the complete deliverables suiting your requirement

Quality is our utmost priority, you will receive 100% error free deliverables

You will get a one-stop solution for all your needs and you can save precious time

Delivering complete structural steel models

Precise fabrication drawings for all structural steel members

Erection drawings with comprehensive details for safely installing the steel structures.

Do what you do the BEST, Outsource to us the rest!

Contact Us

Text us by scanning the QR code